Leading wire forming machine manufacturer specializing in the development of welding technology.

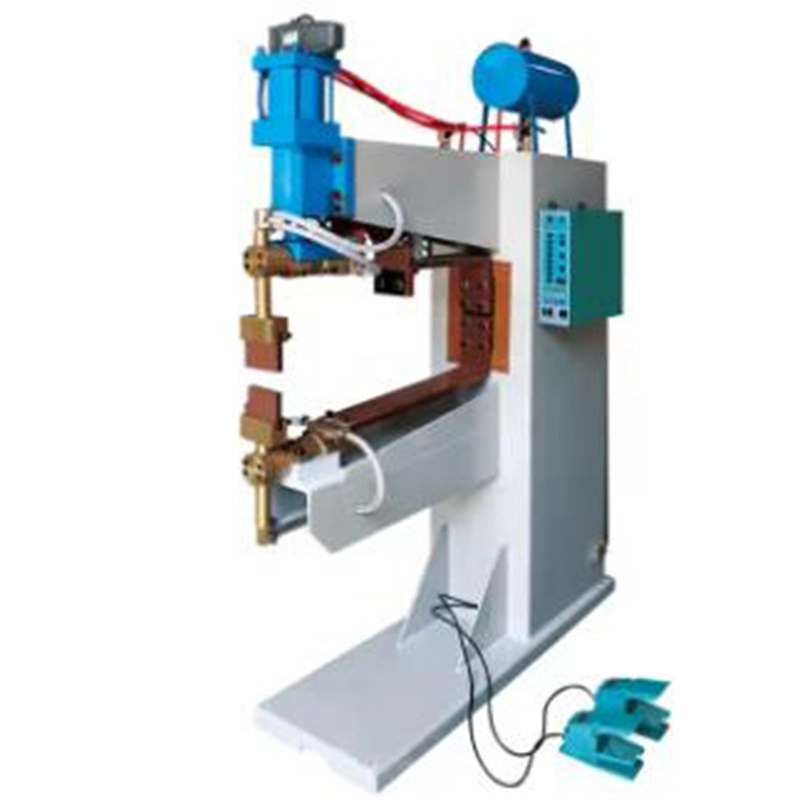

Stainless steel low carbon steel semi-automatic spot welding machine

A spot welder, also known as a resistance spot welding machine, is a specialized tool used in metal fabrication and manufacturing processes to create strong and efficient welds.

Spot welding works by passing an electrical current through the metal parts to be joined, creating heat at the contact points. The heat softens the metal and allows the two pieces to be welded together under pressure, forming a secure bond. Spot welding is commonly used in the automotive industry, appliance manufacturing, and sheet metal fabrication due to its speed, reliability, and effectiveness in creating consistent welds.

Product Description

A spot welder, also known as a resistance spot welding machine, is a specialized tool used in metal fabrication and manufacturing processes to create strong and efficient welds.

Spot welding works by passing an electrical current through the metal parts to be joined, creating heat at the contact points. The heat softens the metal and allows the two pieces to be welded together under pressure, forming a secure bond. Spot welding is commonly used in the automotive industry, appliance manufacturing, and sheet metal fabrication due to its speed, reliability, and effectiveness in creating consistent welds.

Key features of a spot welder include adjustable welding current and time settings, electrode pressure control, and the ability to perform multiple welds in rapid succession. Modern spot welding machines may also have advanced features such as microprocessor control, automatic welding parameter adjustment, and data logging capabilities for quality control and process optimization.

Spot welders come in various sizes and configurations, ranging from portable handheld units for small-scale applications to automated robotic welding systems for high-volume production lines. They are essential for joining thin sheet metal components, wire mesh, and other metal materials quickly and efficiently.

In conclusion, a spot welding machine is a valuable tool for creating strong and reliable welds in metal fabrication, providing manufacturers and fabricators with a versatile and efficient solution for joining metal parts in a variety of industries.

Core Content (Features, Benefits & Use Cases)

Technical parameters

|

project |

rated capacity |

input voltage |

rated frequency |

maximum short circuit current |

cyclic duration factor |

Maximum pressure |

Upper electrode trip |

Lower electrode trip |

Throx depth (deep * high) |

Dimensions between arms |

Arm depth size |

Cooling water |

weight |

Electrode size |

||||||

|

|

|

|

|

|

|

|

work |

assist |

work |

assistant |

|

|

|

|

At 650 |

At 800 |

electrode |

arm |

projection welding |

|

|

|

|

|

|

|

|

|

stroke |

stroke |

stroke |

stroke |

|

|

|

|

|

|

|

|

|

|

|

Model / unit |

KVA |

V |

Hz |

KA |

KA |

% |

N |

mm |

mm |

mm |

mm |

mm |

mm |

mm |

L/min |

Kg |

Kg |

mm |

mm |

mm |

|

XLC-PH-16 |

16 |

380 |

50 |

25 |

|

50 |

200 |

40/80 |

|

55 |

|

350 |

435 |

|

2 |

|

|

14 |

|

|

|

XLC-PH-25 |

25 |

380 |

50 |

30 |

|

50 |

230 |

40/80 |

|

55 |

|

350 |

435 |

|

2 |

|

|

14 |

|

|

|

XLC-PH-35 |

35 |

380 |

50 |

40 |

|

50 |

260 |

40/80 |

|

55 |

|

350 |

435 |

|

3 |

|

|

18 |

|

|

|

XLC-PH-40 |

40 |

380 |

50 |

45 |

|

50 |

300 |

40/80 |

|

55 |

|

350 |

435 |

|

3 |

|

|

18 |

|

|

|

XLC-PH-50 |

50 |

380 |

50 |

55 |

|

50 |

320 |

50/100 |

|

55 |

|

350 |

435 |

|

5 |

|

|

18 |

|

|

|

XLC-PH-63 |

63 |

380 |

50 |

70 |

|

50 |

400 |

50/100 |

|

55 |

|

800 |

435 |

|

5 |

|

|

18 |

|

|

|

XLC-PH-75 |

75 |

380 |

50 |

80 |

|

50 |

450 |

50/100 |

|

55 |

|

800 |

435 |

|

8 |

|

|

20 |

|

|

|

XLC-PH-80 |

80 |

380 |

50 |

90 |

|

50 |

500 |

50/100 |

|

55 |

|

800 |

435 |

|

8 |

|

|

20 |

|

|

|

XLC-PH-100 |

100 |

380 |

50 |

110 |

|

50 |

550 |

50/100 |

|

55 |

|

800 |

435 |

|

10 |

|

|

20 |

|

|

|

XLC-PH-125 |

125 |

380 |

50 |

150 |

|

50 |

600 |

50/100 |

|

55 |

|

800 |

435 |

|

10 |

|

|

24 |

|

|

|

XLC-PH-160 |

160 |

380 |

50 |

200 |

|

50 |

620 |

50/100 |

|

55 |

|

800 |

435 |

|

12 |

|

|

24 |

|

|

|

XLC-PH-200 |

200 |

380 |

50 |

230 |

|

50 |

650 |

50/100 |

|

55 |

|

800 |

435 |

|

12 |

|

|

24 |

|

|

Applications