Leading wire forming machine manufacturer specializing in the development of welding technology.

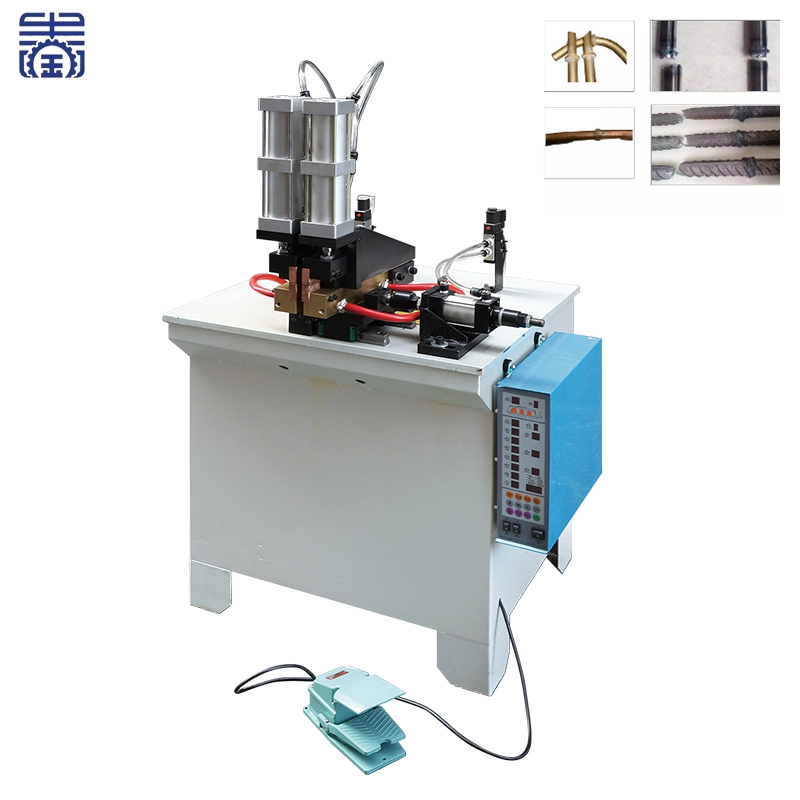

Pneumatic foot-operated Type Wire butt welding machine For copper/aluminum/iron pipe

Pneumatic foot-operated wire butt welding machine is designed for welding various types of pipes, including copper, aluminum, and iron, using a butt welding technique.

One of the primary advantages of using a welding machine is its ability to create durable and high-strength welds that can withstand substantial loads and stresses. Welded joints are often stronger than the base metal itself, making welding an essential process in industries where structural integrity and reliability are critical.

Product Description

A welding machine, also known as a welder, is a versatile tool used in metalworking, construction, and manufacturing processes to join metal components together. Welding machines work by creating a strong and permanent bond between two or more pieces of metal through the application of heat and pressure.

One of the primary advantages of using a welding machine is its ability to create durable and high-strength welds that can withstand substantial loads and stresses. Welded joints are often stronger than the base metal itself, making welding an essential process in industries where structural integrity and reliability are critical.

Welding machines offer a variety of welding techniques, including arc welding, MIG welding, TIG welding, and spot welding, each suited to different applications and metal types. This versatility allows welders to work with a wide range of materials, from steel and aluminum to exotic metals like titanium and Inconel.

Another key advantage of welding machines is their efficiency and speed in joining metal parts. With the right equipment and training, welders can create precise and clean welds quickly, making welding a cost-effective solution for manufacturing processes that require fast turnaround times.

Additionally, welding machines can be used in various settings, from workshops and construction sites to industrial manufacturing facilities and automotive repair shops. Portable welding machines allow for on-site repairs and maintenance, while larger industrial welding machines are used for mass production and assembly line welding.

In conclusion, welding machines offer numerous advantages, including the ability to create strong and reliable welds, versatility in working with various materials, efficiency in joining metal components, and adaptability to different work environments. As a fundamental tool in metalworking and fabrication, welding machines play a crucial role in producing high-quality products and structures across industries.

Technical parameters

|

project |

rated capacity |

input voltage |

rated frequency |

maximum short circuit current |

cyclic duration factor |

Maximum pressure |

Upper electrode trip |

Lower electrode trip |

Cooling water |

weight |

Electrode size |

Welding ability |

||||||

|

Work |

assist |

work |

assist |

At 650 |

At 800 |

electrode |

arm |

[化] projection welding |

round wire |

Square flat line |

||||||||

|

stroke |

stroke |

stroke |

stroke |

|

|

|

|

|

|

|

|

|||||||

|

Model / unit |

KVA |

V |

Hz |

KA |

% |

N |

mm |

mm |

mm |

mm |

L/min |

Kg |

Kg |

mm |

mm |

mm |

mm |

mm |

|

XLC-UN-16 |

16 |

380 |

50 |

25 |

30 |

200 |

40/80 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-25 |

25 |

380 |

50 |

30 |

30 |

230 |

40/80 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-40 |

40 |

380 |

50 |

45 |

30 |

300 |

40/80 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-50 |

50 |

380 |

50 |

55 |

30 |

300 |

40/80 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-63 |

63 |

380 |

50 |

70 |

30 |

400 |

50/100 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-80 |

80 |

380 |

50 |

90 |

30 |

500 |

50/100 |

|

|

|

|

|

|

|

|

|

|

|

|

XLC-UN-100 |

100 |

380 |

50 |

110 |

30 |

550 |

50/100 |

|

|

|

|

|

|

|

|

|

|

|

Applications