Leading wire forming machine manufacturer specializing in the development of welding technology.

Automatic Wire Winding Machine by XLC

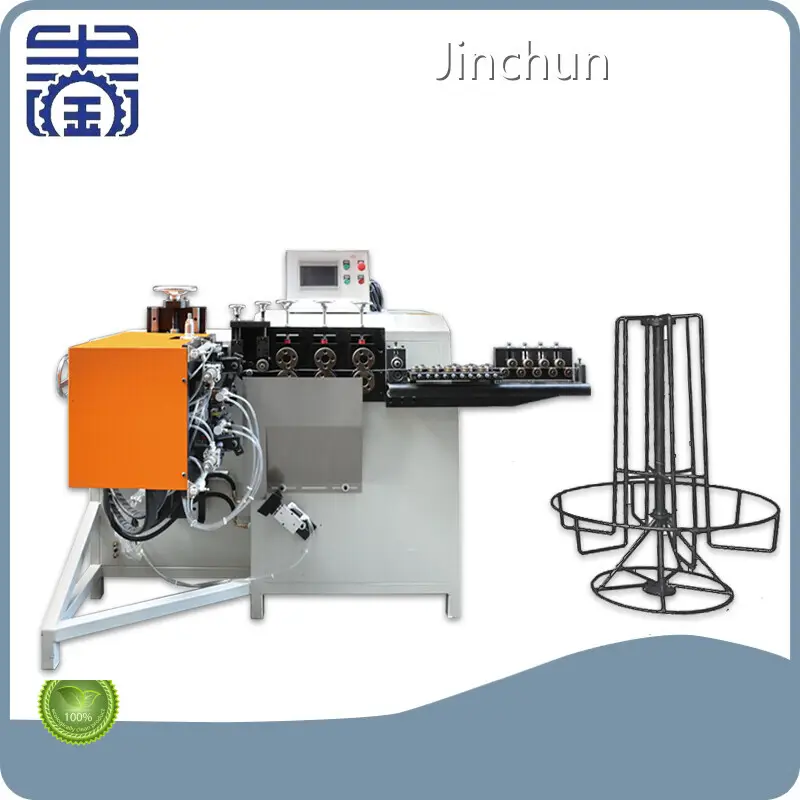

Product Overview

- The Automatic Wire Winding Machine by XLC is designed to handle various types of wire, different coil configurations, and specific winding requirements.

- It ensures consistent winding tension and precise turns, resulting in high-quality coils with uniform thickness and proper layering.

- This versatile machine is essential for producing coils used in transformers, electric motors, solenoids, inductors, and other electrical components.

Product Features

- Programmable features allow for customization and flexibility, making it an indispensable tool in the coil winding industry.

- Technical parameters include a servo wire transmission motor, servo cut off motor, different ring diameter ranges, input voltage, welding power, compressed air pressure, cooling water flow, and overall equipment dimensions.

Product Value

- Enhances productivity, reduces labor costs, and improves the overall quality of products for manufacturers using this machine.

- Enables manufacturers to create high-quality coils with uniform thickness and proper layering, which are essential for various electrical components.

Product Advantages

- Consistent winding tension and precise turns ensure high-quality coils with uniform thickness and proper layering.

- Programmable features allow for customization and flexibility in producing coils for transformers, electric motors, solenoids, inductors, and other electrical components.

Application Scenarios

- The Automatic Wire Winding Machine can be used in a variety of industries to play a certain role, including the production of coils for transformers, electric motors, solenoids, inductors, and other electrical components.