Leading wire forming machine manufacturer specializing in the development of welding technology.

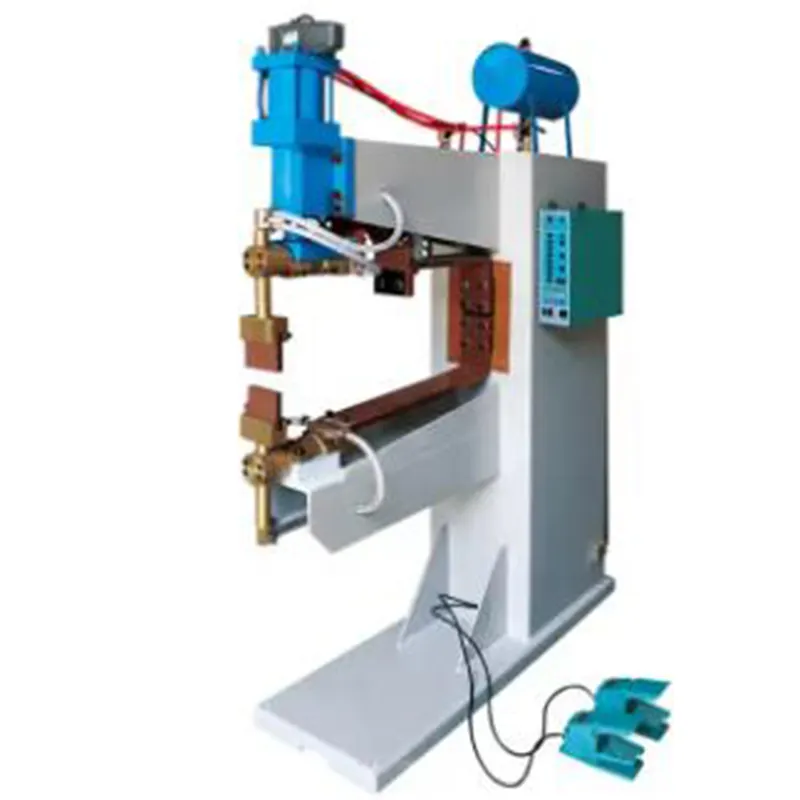

Aluminum Spot Welder by XLC

Product Overview

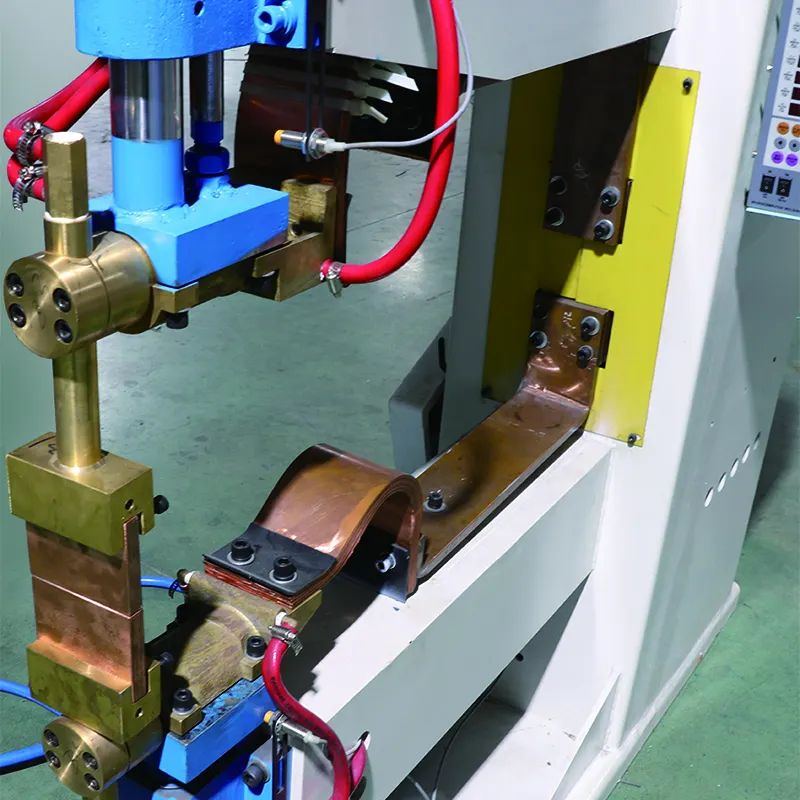

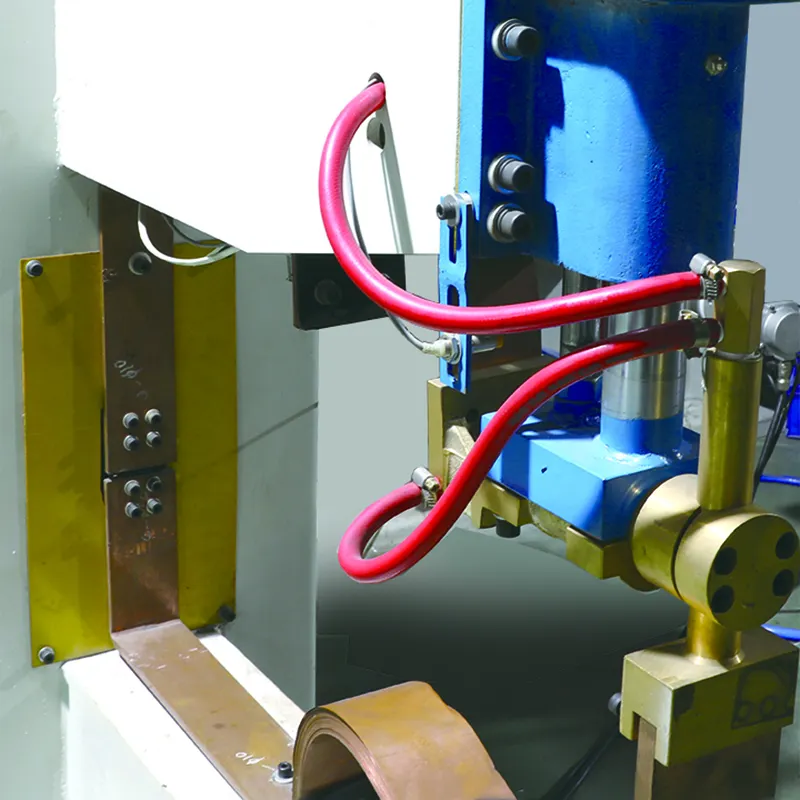

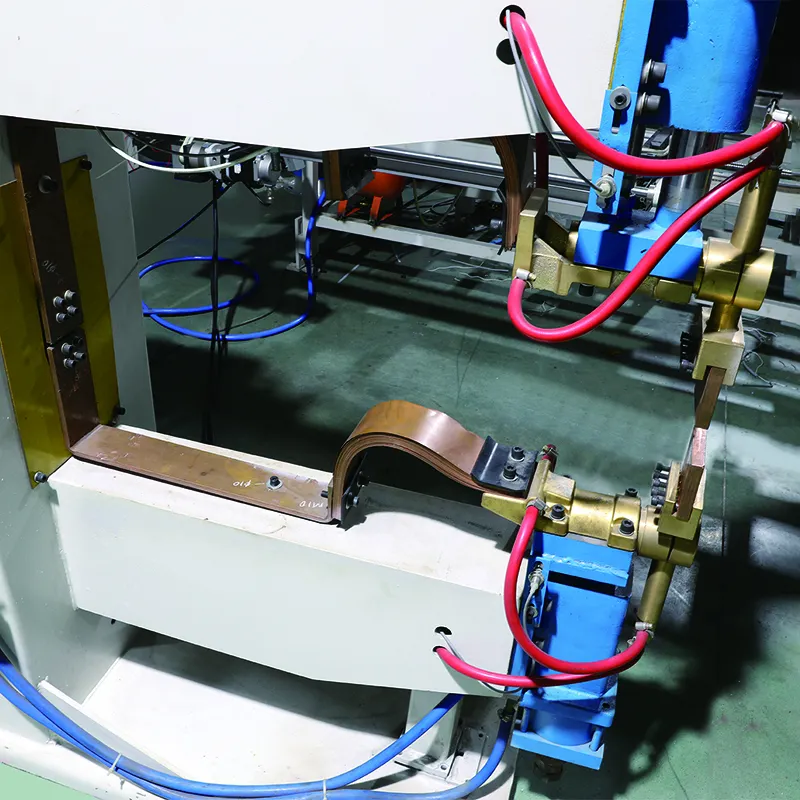

**Product Overview**: The Aluminum Spot Welder by XLC is a specialized tool used in metal fabrication and manufacturing processes to create strong and efficient welds. It passes an electrical current through metal parts to be joined, creating heat at the contact points to soften the metal and allow the two pieces to be welded together under pressure.

Product Features

**Product Features**: Key features of this spot welder include adjustable welding current and time settings, electrode pressure control, and the ability to perform multiple welds in rapid succession. It also has advanced features such as microprocessor control, automatic welding parameter adjustment, and data logging capabilities for quality control and process optimization.

Product Value

**Product Value**: The Aluminum Spot Welder provides manufacturers and fabricators with a versatile and efficient solution for joining metal parts in a variety of industries. It is essential for creating strong and reliable welds in metal fabrication, offering speed, reliability, and effectiveness in creating consistent welds.

Product Advantages

**Product Advantages**: The spot welder by XLC offers superior performance and a long service life, making it competitive in the market. It adapts to market needs and is widely used at home and abroad, providing manufacturers with a valuable tool for joining thin sheet metal components, wire mesh, and other metal materials quickly and efficiently.

Application Scenarios

**Application Scenarios**: This spot welder is commonly used in the automotive industry, appliance manufacturing, and sheet metal fabrication due to its speed, reliability, and effectiveness in creating consistent welds. It comes in various sizes and configurations, from portable handheld units for small-scale applications to automated robotic welding systems for high-volume production lines.