Leading wire forming machine manufacturer specializing in the development of welding technology.

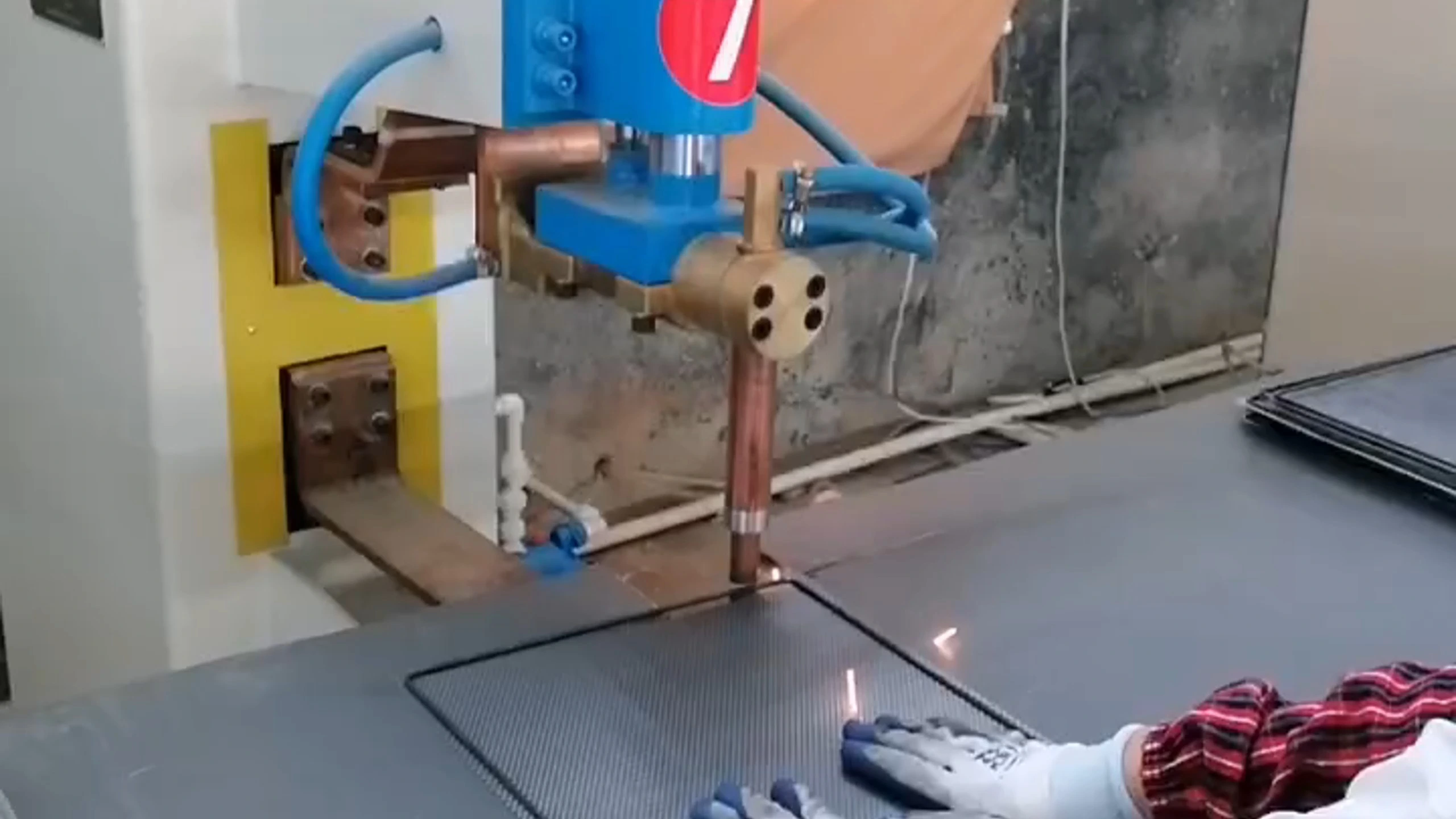

Automatic Robotic Spot Welding Machine with Semi-Automatic Resistance Welding for Shopping Cart Wire Mesh & Bird Cage Mesh Production

About This Product

Key Features:

1. Robotic Arm & XY-Axis Control:

.Equipped with a 6-axis robotic arm for 360° welding accessibility, enabling seamless welding of complex wire mesh geometries (e.g., rectangular frames, circular patterns).

.Integrated XY-axis servo-driven motion system with 0.5 m/s feeding speed for precise positioning and alignment of wire mesh components

2. Semi-Automatic Resistance Welding:

.Utilizes medium-frequency inverter DC power supply for stable current output (up to 38,000 A) and minimal spatter, ideal for welding stainless steel, carbon steel, and galvanized wire

.Adjustable welding parameters (current, time, pressure) via PLC touchscreen interface, supporting one-key switching between 18+ welding models for diverse mesh specifications

3. High-Precision Welding:

.Features 13 electrodes for multi-spot welding, enabling simultaneous formation of 10–20 weld points per cycle with ±0.1 mm positioning accuracy

Technical Parameters

|

Voltage |

380V |

Type |

Spot Welding Machine |

|

Warranty Period |

1 year |

Weight (KG) |

400 |

|

Place of Origin |

Guangdong, China |

Video Inspection before Shipment |

Available |

|

Mechanical Test Report |

Available |

Core Components |

PLC, Engine, Motor |

|

Brand |

JCXLC |

Core Selling Point |

Welding Machine |

|

Max welding thickness |

32mm |

Maximum Short-Circuit Current |

200KA |

|

Maximum Pressure |

620N |

Stroke of Upper Electrode |

50/100mm |

|

Stroke of Lower Electrode |

55mm |

The Max Welding Length(Deep*Height) |

800mm |

|

Dimension Between Arms |

435mm |

Cooling Water Volume |

12L/min |

|

Electrode Size |

24mm |

Machine Dimensions |

1250*600*1800mm |

| Delivery Time | ||

|

Quantity (sets) |

1 - 1 |

> 1 |

|

Eastern Time in the US (days) |

15 |

To be determined |

| Customization | ||

|

Customized logo |

Minimum Order Quantity |

1 set |

|

Customized packaging |

Minimum Order Quantity |

1 set |

|

Graphic customization |

Minimum Order Quantity |

1 set |

Product Display

Product Information

|

Brand Name |

Jinchun / Xinliancheng |

|

Country of Origin |

Foshan, Guangdong, China |

|

Loading Port |

Foshan / Shenzhen / Guangzhou |

|

Payment Terms |

EXW / FOB / CIF |

product introduce

Faq