One Stop Customization

Solution for Wire Ring Making Machine

Precision Wire Ring Forming & Welding Machines | 0.02mm Accuracy | 10-Year Lifespan

Seamless Integration of Forming & Welding | Save 40% Labor Cost | CE/ISO9001 Certified

Firstly, a coil winding machine significantly improves the efficiency of the winding process by automating the repetitive and labor-intensive task of winding coils. This not only reduces manual labor costs but also increases production output and consistency, leading to higher overall productivity.

Welding Technology: Resistance Butt Welding or TIG/MIG Welding System

Wire Compatibility: Low Carbon Steel Wire, Stainless Steel Wire, Galvanized Wire

Wire Diameter Range: 3.0 mm to 10.0 mm (Customizable)

Ring Diameter Range: 50 mm to 500 mm (Adjustable)

Production Speed: Up to 800-1200 rings per hour (dependent on wire diameter & ring size)

Power Supply: 380V/415V, 3-Phase, 50/60Hz

Control System: PLC with Touchscreen HMI for parameter setting and diagnostics

Frame Construction: Heavy-duty welded steel with reinforced stress points for vibration-free operation

Choose the machine you want to know more

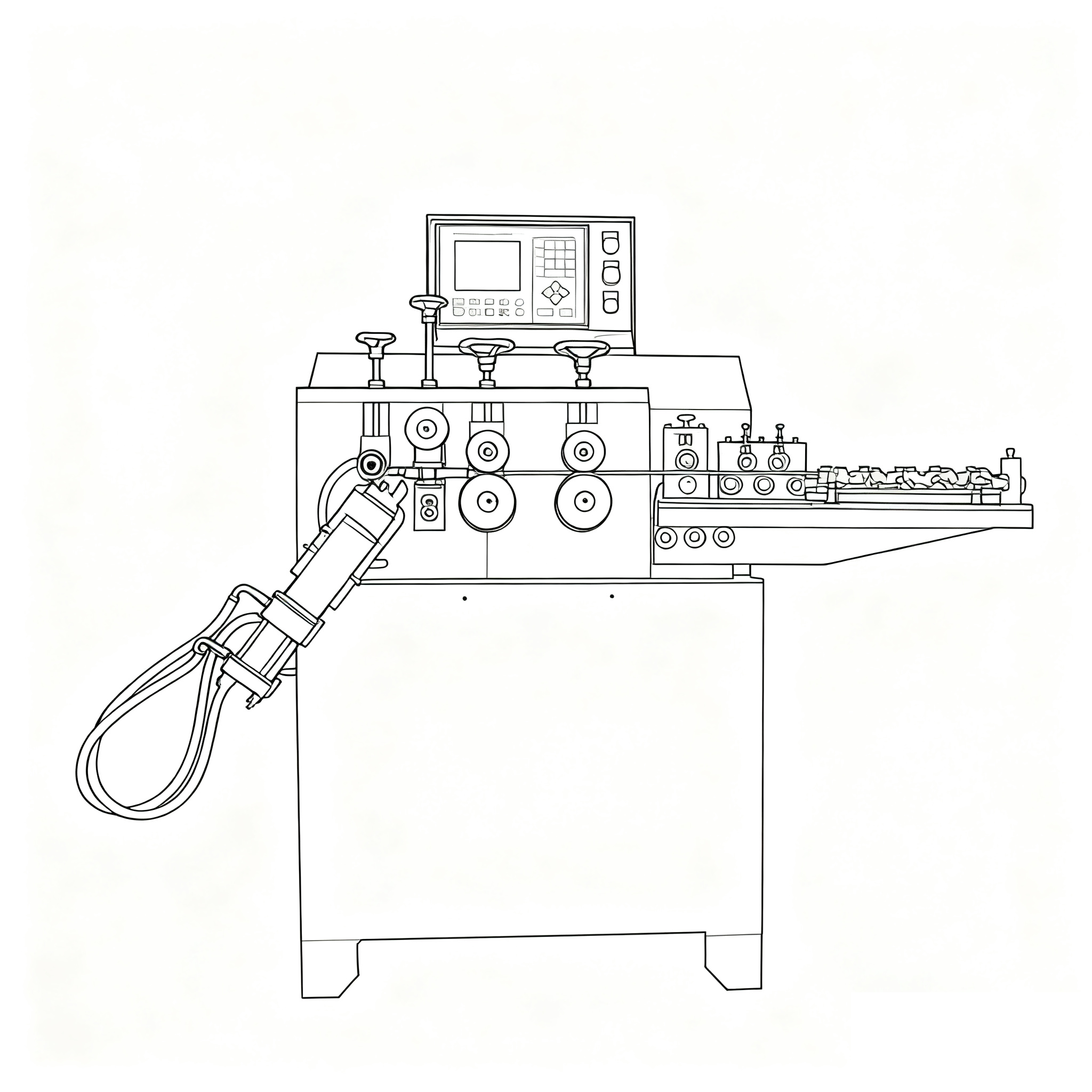

Ring Making Forming Machine

High-speed circle forming for round or flat bar materials (iron, stainless steel, aluminum, copper) with diameters of 1-16mm; requires only a mold change. The circle diameter range is 30mm-3000mm (customizable). Production speed is 20-40 circles per minute with an accuracy of up to 0.02mm. Produces flat, round rings without scratches and with a smooth surface, achieving a high yield rate of 99.9%. Universal molds minimize downtime for changeovers. Custom functions like welding or stamping are available. Features a multilingual intelligent system with both buttons and a touch screen, allowing beginners to get started within 30 minutes. Applicable for furniture, hardware, automotive/motorcycle parts, and kitchenware industries.

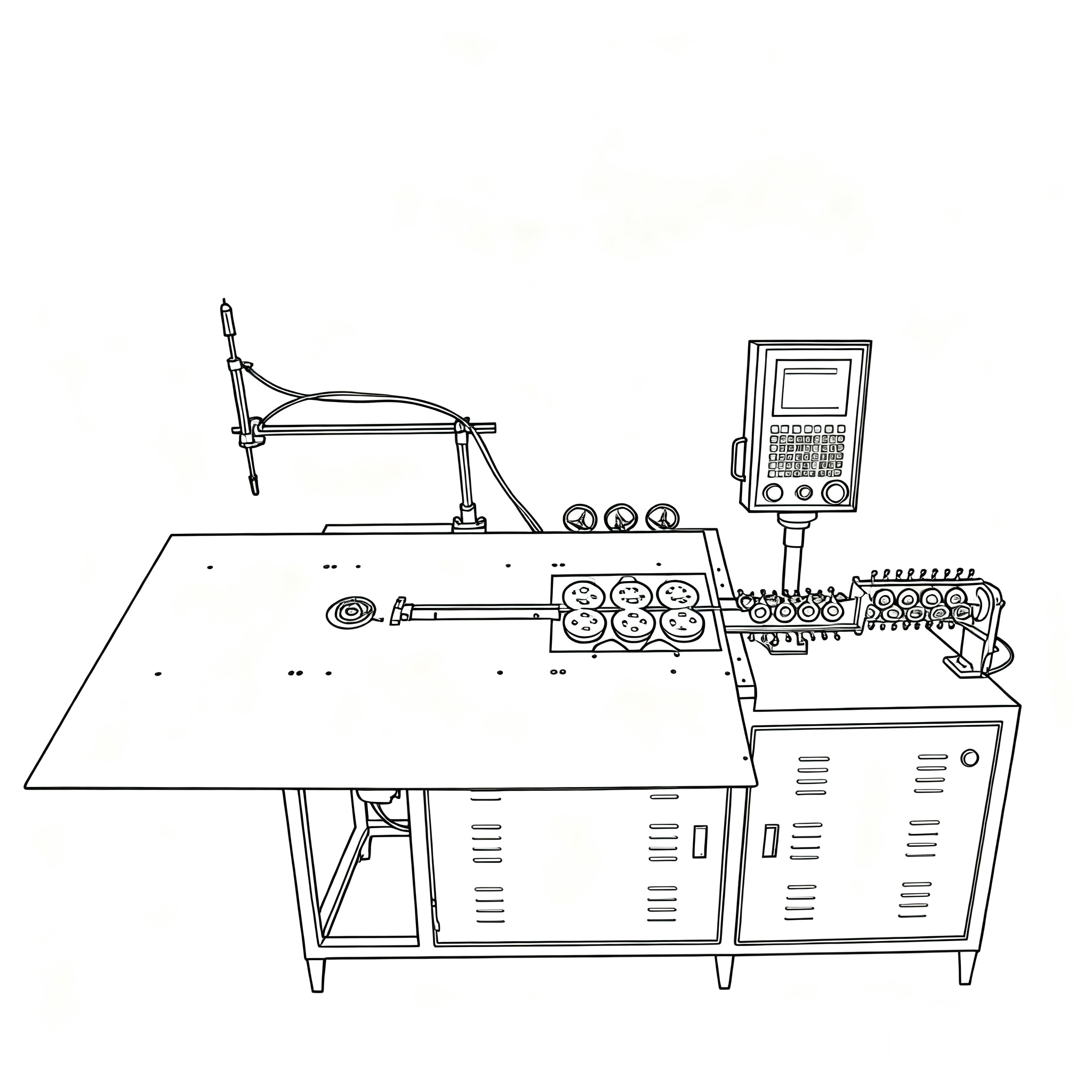

2D Wire Bending Machine

Our range of CNC wire bending machines is designed to cater to your production needs, offering a suitable solution for bent parts from both wire and profile material. With various series available for high-performance applications, our machines can handle wire diameters ranging from 1.5 mm up to 16.0 mm. Equipped with flexible options and additional features, JINCHUN wire bending machines are a cost-effective solution for all your production requirements.

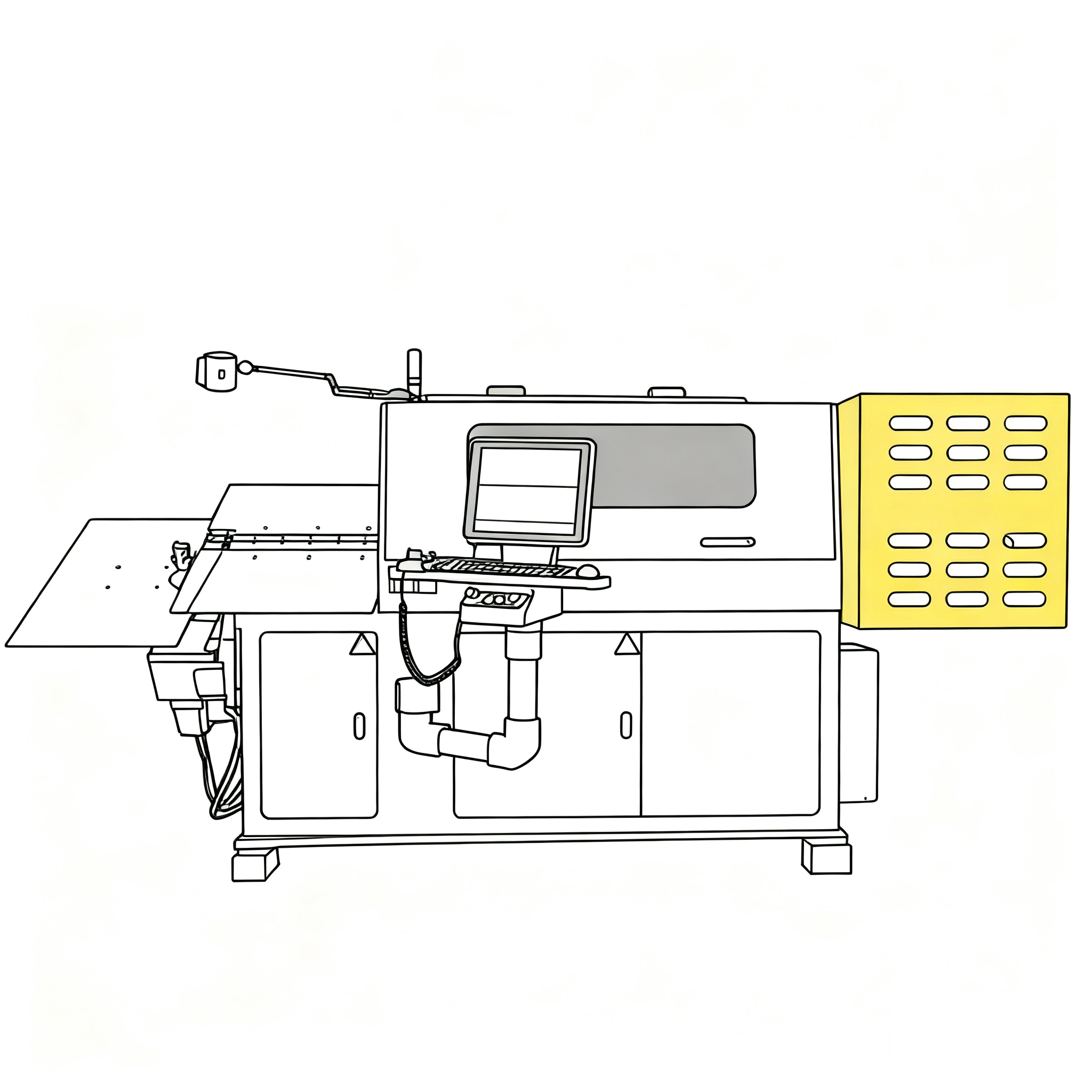

3D Wire Bending Machine

Suitable for round or flat bar materials (iron, stainless steel, aluminum, copper) with diameters of 1-16mm; requires only a mold change. Forms 15-30 3D parts per minute with an accuracy of up to 0.02mm. Primarily designed for smaller volume precision 3D products. The machine utilizes a gearbox to synchronously rotate the product for multi-angle forming. Configurable with 7-13 axes, enabling rapid production of complex 3D items. Features a multilingual intelligent system with both buttons and a touch screen, allowing beginners to get started within 2 hours. Can store up to 10,000 programs. Ideal for automotive/motorcycle parts, fasteners, furniture, and craft industries.

Wire Straightening and Cutting Machine

The Wire Straightening Machine is a high-quality product designed to efficiently straighten and cut wires of various materials, such as steel, copper, and aluminum. The machine provides precise and accurate straightening, reducing the time and effort required for manual wire straightening. Its user-friendly interface and adjustable settings make it suitable for a wide range of wire diameters, making it an essential tool for manufacturers and fabricators in the construction, automotive, and electronics industries.

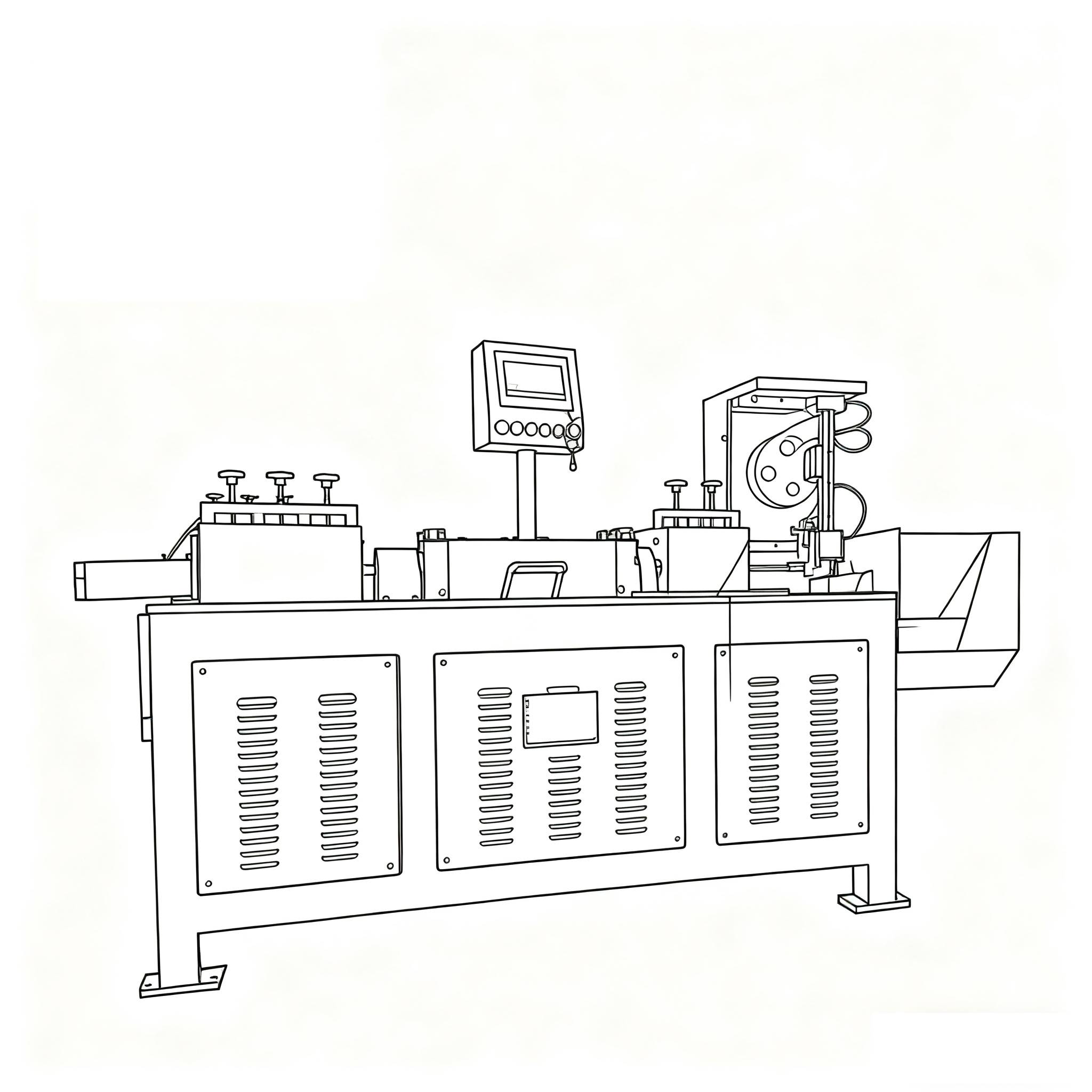

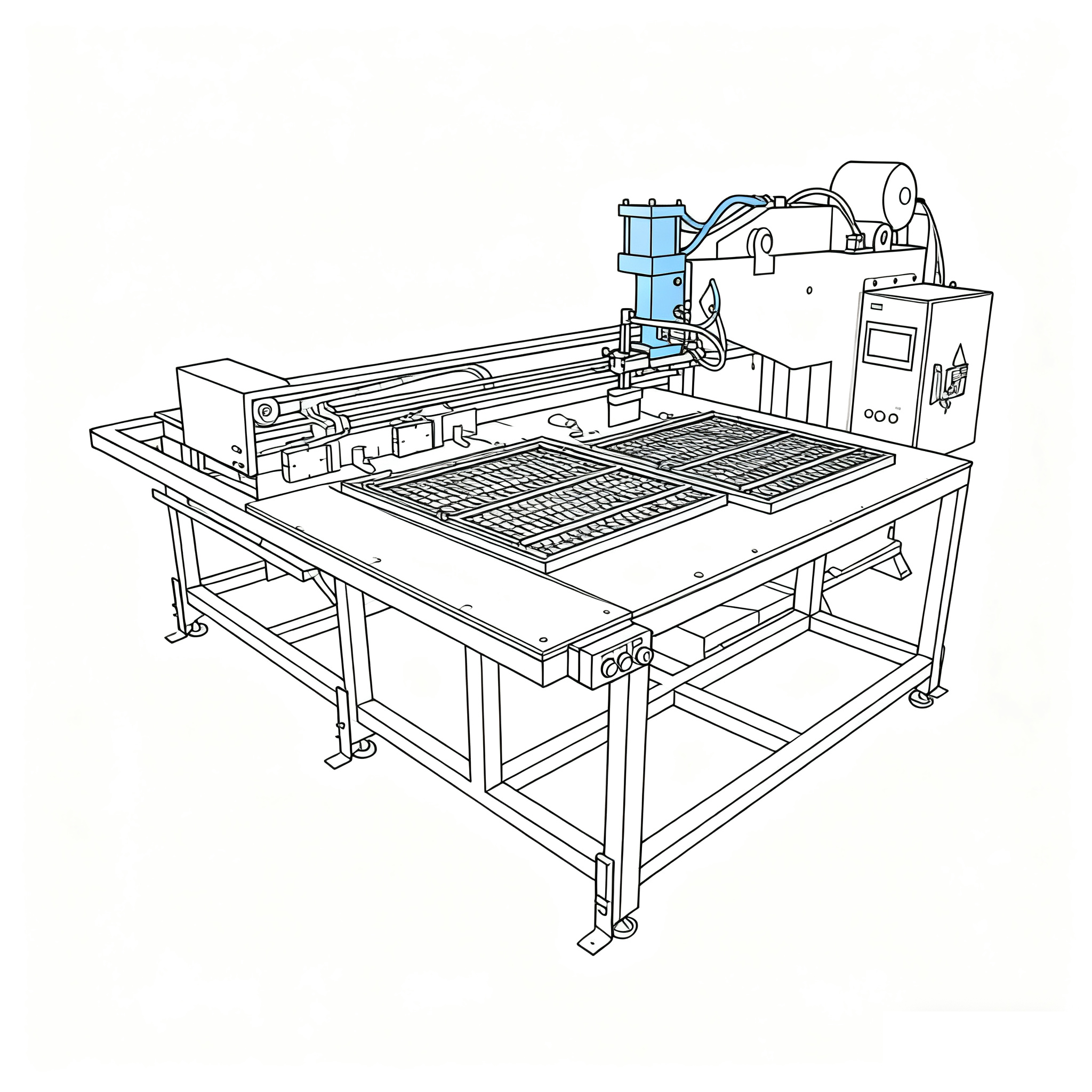

Mesh Welding Machine

Jinchun Machinery diverse mesh forming range includes:

Spot Welders --- Rapid single-point welding with servo-driven precision, ideal for automotive parts and electronics.

Seam/Continuous Welders --- Uniform welds for mesh panels and fences, featuring medium-frequency stability and high-speed.

XY CNC Platforms --- Programmable automation for intricate patterns, used in aerospace and medical devices.

Multi-Cylinder Gantry Systems --- Heavy-duty capacity (230kVA) for structural frameworks, with 1800mm/s speed and 5000N clamping force

Customized Machines

Jinchun delivers fully customized wire forming solutions for industrial automation, offering tailored features like heading, pointing, chamfering, punching, flattening, and clamping. Our machines integrate precision servo systems and multi-axis control for consistent output, ideal for automotive, electronics, and machinery sectors. Achieve ±0.5mm accuracy with rapid cycle times, supporting 2–8mm wire diameters and complex geometries. Scalable and modular, we adapt to your production needs. Contact us for bespoke designs!

We understand you don’t just need a machine; you need a production system that generates continuous value. Our team of experts will analyze your product drawings, capacity needs, and budget to deliver a complete “turnkey” solution, from single machines to full production lines.