Leading wire forming machine manufacturer specializing in the development of welding technology.

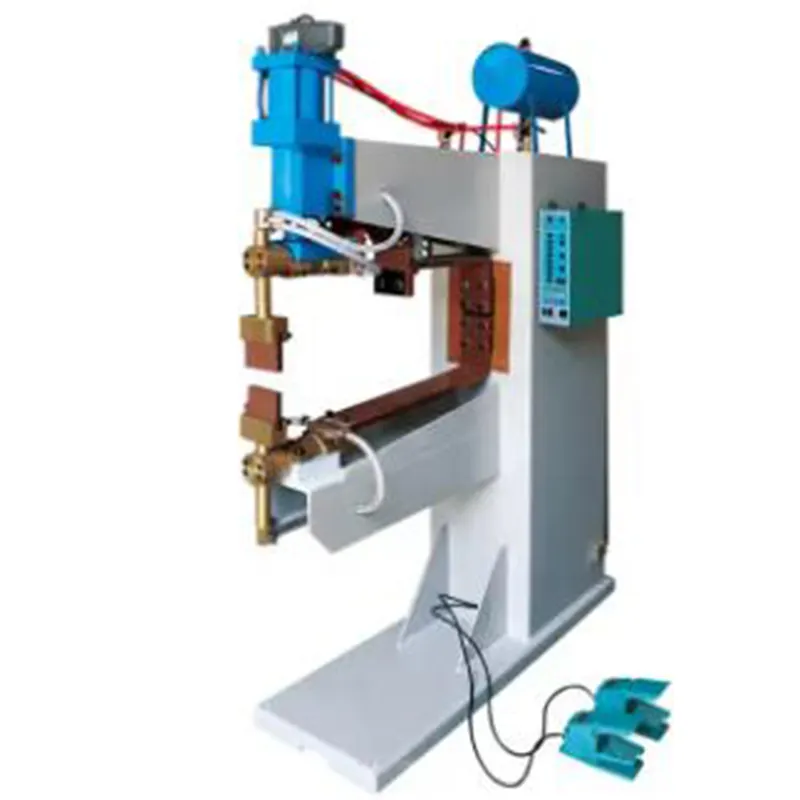

Gtaw Welding Equipment - - XLC-2

Product Overview

- The "Gtaw Welding Equipment - XLC" is a spot welder used in metal fabrication and manufacturing processes.

- It creates strong and efficient welds by passing an electrical current through metal parts.

- Key features include adjustable welding settings, electrode pressure control, and the ability to perform multiple welds rapidly.

- It comes in various sizes from portable handheld units to automated robotic systems for different applications.

- A valuable tool for creating strong and reliable welds in metal fabrication in a variety of industries.

Product Features

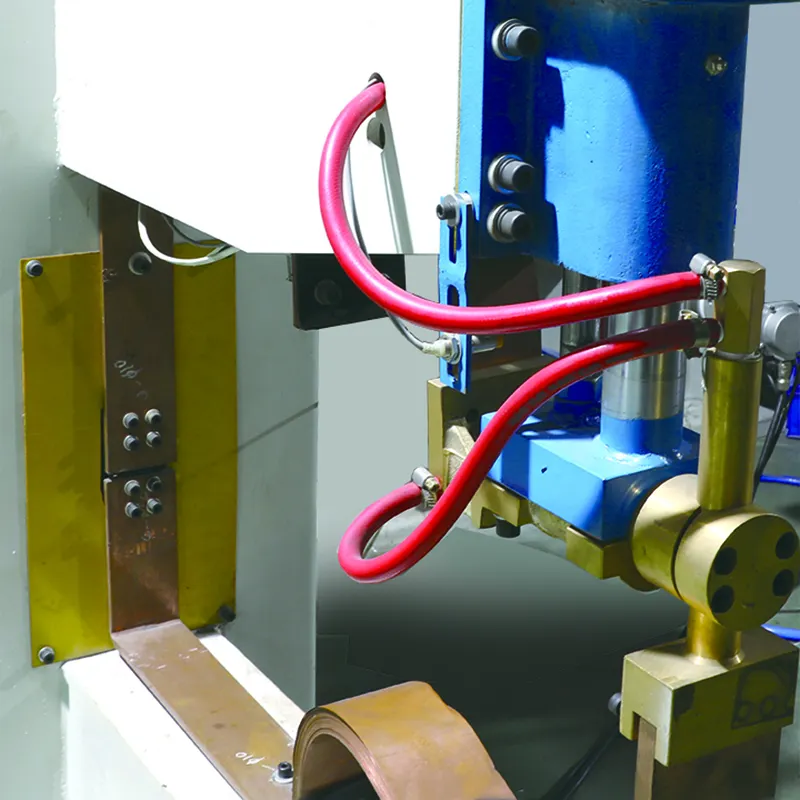

- Adjustable welding settings

- Electrode pressure control

- Ability to perform multiple welds rapidly

- Portable handheld units to automated robotic systems

- Strong and reliable welds in metal fabrication

Product Value

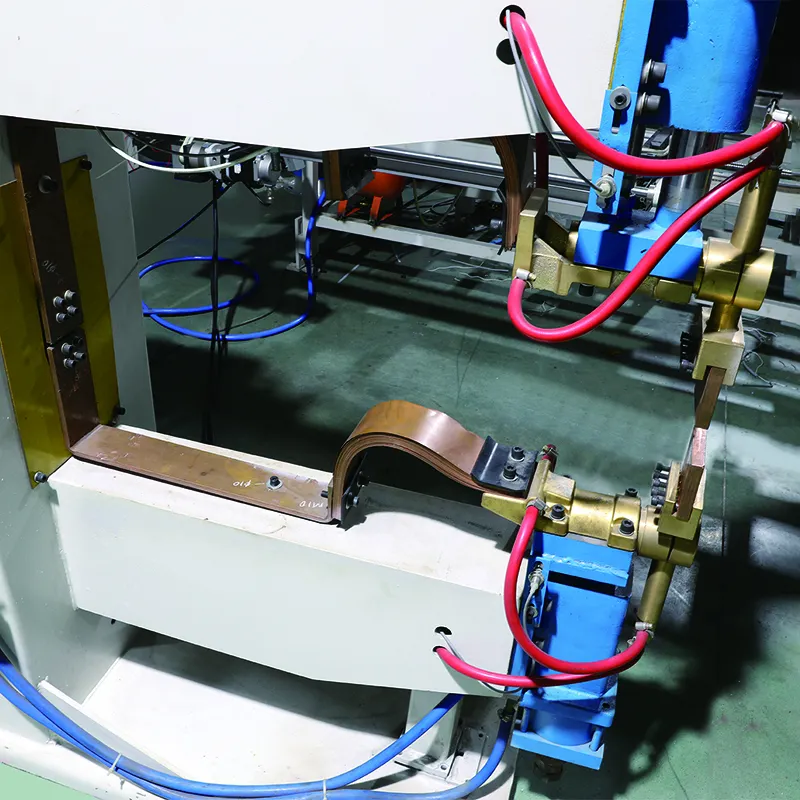

- Provides manufacturers and fabricators with a versatile and efficient solution for joining metal parts.

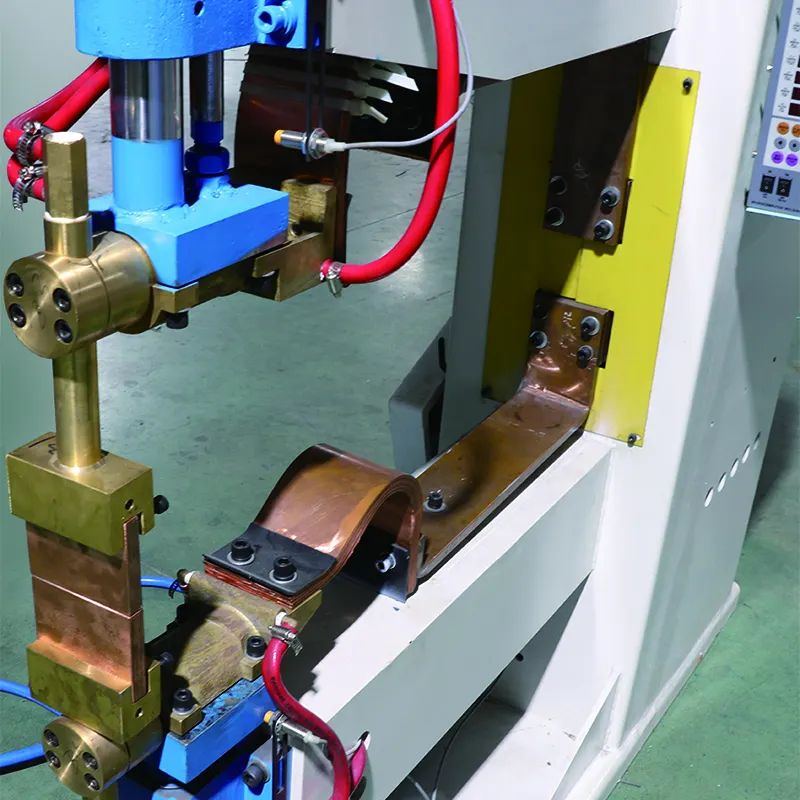

- Essential for joining thin sheet metal components, wire mesh, and other metal materials quickly and efficiently.

- Ensures speed, reliability, and effectiveness in creating consistent welds.

Product Advantages

- Modern features such as microprocessor control, automatic welding parameter adjustment, and data logging for quality control.

- Versatile tool used in the automotive industry, appliance manufacturing, and sheet metal fabrication.

- Creates strong and efficient welds by passing an electrical current through metal parts.

Application Scenarios

- Used in metal fabrication and manufacturing processes.

- Commonly used in the automotive industry, appliance manufacturing, and sheet metal fabrication.

- Ideal for joining thin sheet metal components, wire mesh, and other metal materials.

- Provides a versatile and efficient solution for joining metal parts in a variety of industries.