Leading wire forming machine manufacturer specializing in the development of welding technology.

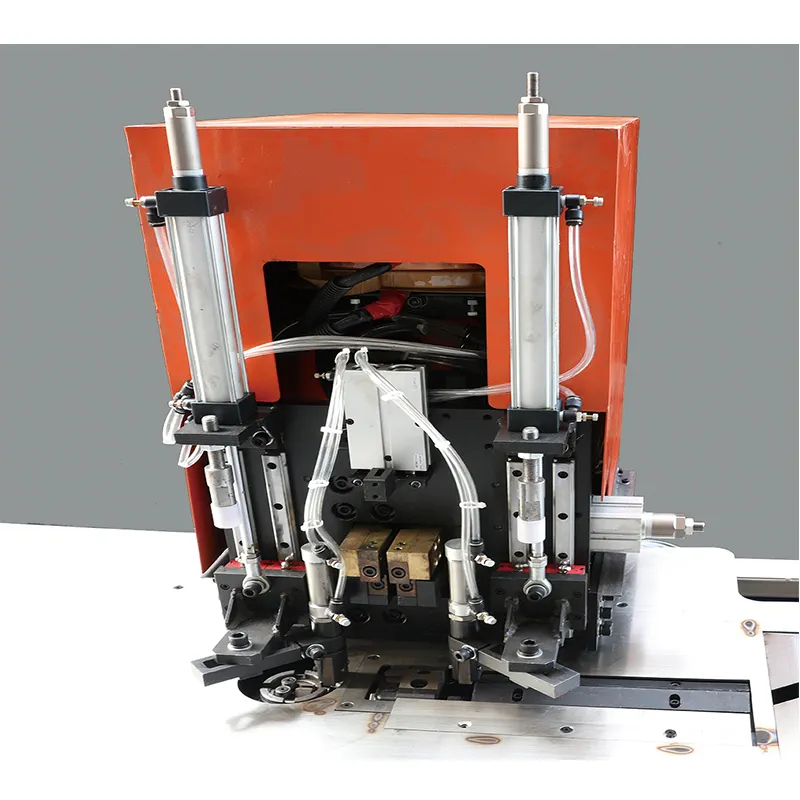

Automatic Wire Bending Machine - - XLC-2

Product Overview

The XLC-2 automatic wire bending machine is a highly standardized product that undergoes strict testing before leaving the factory. It is designed to bend tubes or pipes into complex shapes with high accuracy and repeatability.

Product Features

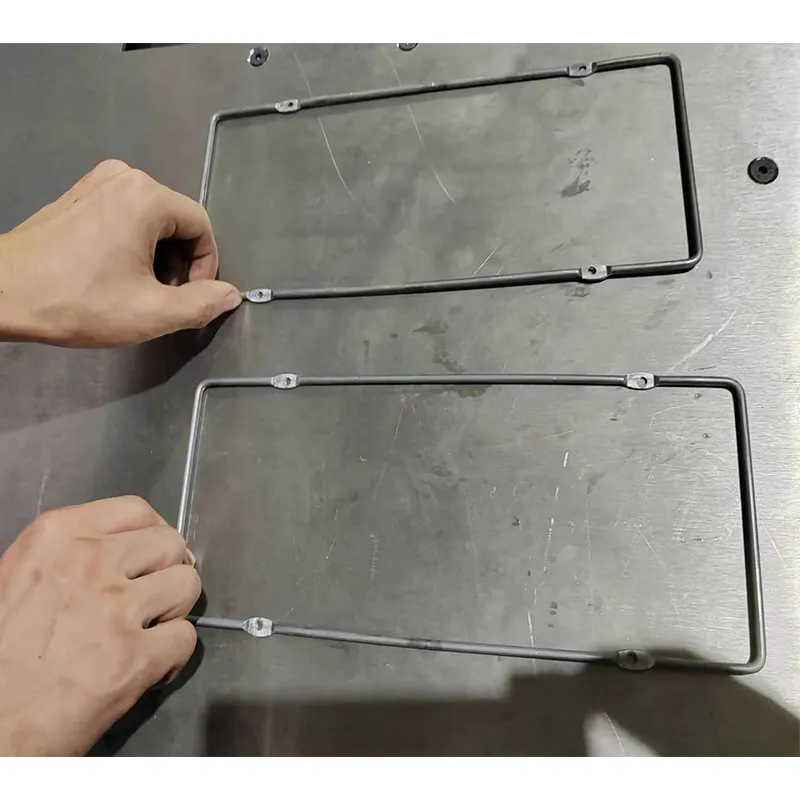

The machine has a user-friendly interface for easy programming of bending and welding parameters, ensuring consistency in production. It offers dual functionality of bending and welding in one machine, saving time and costs associated with separate processes.

Product Value

The tube bending and welding machine offers efficiency, accuracy, versatility, and cost-saving benefits, making it an indispensable tool for businesses seeking to optimize their manufacturing processes and meet market demands.

Product Advantages

The XLC-2 automatic wire bending machine has 3 axes, high-quality materials for bend molds and roulettes, and a maximum bending speed of 150/min. It also has a pneumatic system, electromagnetic valves, and a servo system, as well as a control panel with key and touch screen PLC dual system.

Application Scenarios

The XLC-2 automatic wire bending machine is suitable for industries like automotive, aerospace, and construction for producing structures such as frame components, exhaust systems, and handrails. It is ideal for manufacturers looking to streamline production operations and save costs.