Leading wire forming machine manufacturer specializing in the development of welding technology.

Heavy Duty Hydraulic Press for Bird Cage Wire Mesh Stamping and Forming

About This Product

Multifunctional Bending Capability

1. Ultra-High Tonnage Capacity

- Delivers up to 1000 tons of pressing force 1 10 , ensuring reliable performance for thick metal sheets and complex forming tasks.

- Adjustable stroke length (e.9., 25-50 mm) and pressure settings enable precise control over material deformation.

2.Heavy-Duty Frame Design

- Built with industrial-grade steel and reinforced H-frame structure for maximum rigidity, minimizing deflection during high-force operations.

- Open workspace design allows easy access for large workpieces, ideal for wire mesh and multi-axis stamping

3.Advanced Hydraulic System

- Equipped with a dual-stage hydraulic pump for smooth, energy-efficient operation and rapid cycling

- Integrated safety features: overload protection, emergency stop buttons, and automatic pressure relief valves.

4.Precision control&Automation

- Programmable CNC interface for customizable stroke speed, pressure, and cycle parameters

- Compatible with automated feeding systems (e.g., servo-driven rollers) to enhance throughput and reduce manual intervention.

5.Versatile Applications

- Optimized for bird cage wire mesh fabrication, including punching, bending, and shearing

- Suitable for automotive parts, aerospace components, and industrial hardware manufacturing.

Technical Parameters

|

Voltage |

380V |

Type |

Heavy-Duty Hydraulic Press Machine |

|

Warranty Period |

1 year |

Weight (KG) |

|

|

Place of Origin |

Guangdong, China |

Video Inspection before Shipment |

Available |

|

Mechanical Test Report |

Available |

Core Components |

PLC, Engine, Gearbox, Motor, Gears |

|

Brand |

JCXLC |

Core Selling Point |

Multifunctional |

|

Normial Force |

1000 Tons (Adjustable) |

Stroke Length |

25–50 mm (Customizable) |

|

Work Table Size |

2000 mm (L) x 1800 mm (W) |

Hydraulic Pressure |

250–350 Bar |

|

Power Consumption |

60 kW |

Speed |

4–10 mm/s (Pressing) |

| Delivery Time | ||

|

Quantity (sets) |

1 - 1 |

> 1 |

|

Eastern Time in the US (days) |

15 |

To be determined |

| Customization | ||

|

Customized logo |

Minimum Order Quantity |

1 set |

|

Customized packaging |

Minimum Order Quantity |

1 set |

|

Graphic customization |

Minimum Order Quantity |

1 set |

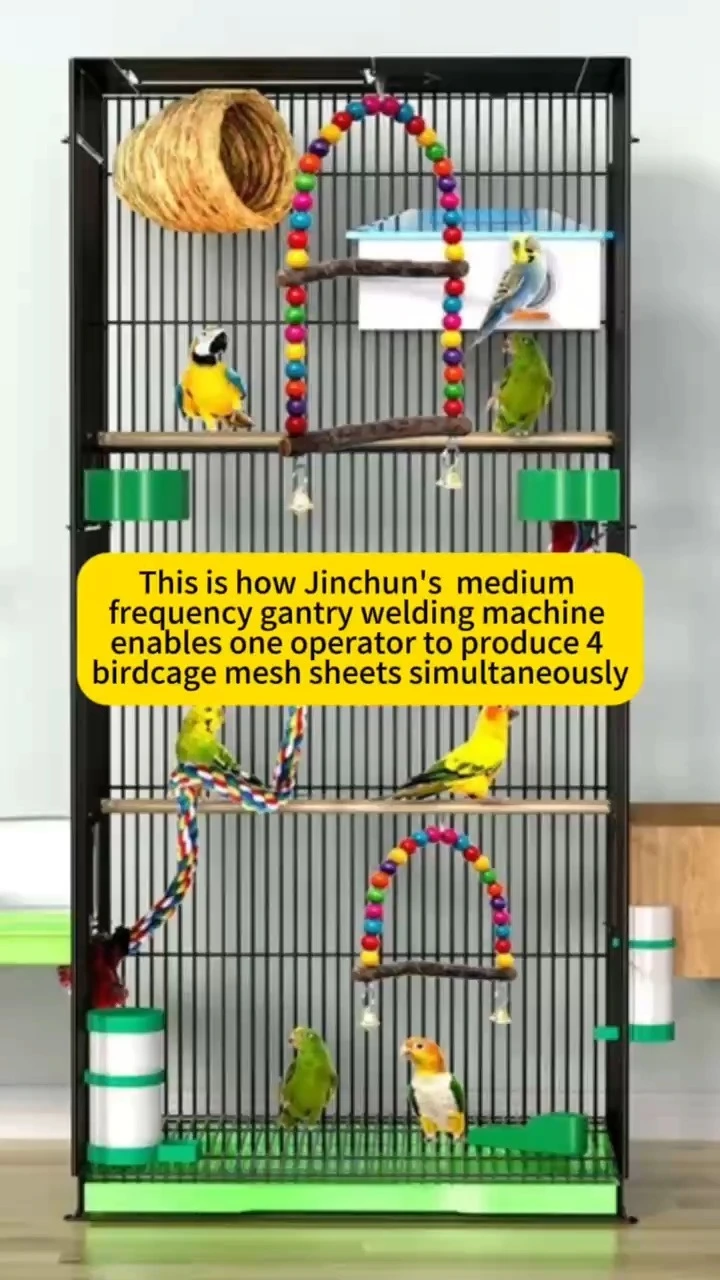

Product Display

Product Information

|

Brand Name |

Jinchun / Xinliancheng |

|

Country of Origin |

Foshan, Guangdong, China |

|

Loading Port |

Foshan / Shenzhen / Guangzhou |

|

Payment Terms |

EXW / FOB / CIF |

product introduce

Faq