Leading wire forming machine manufacturer specializing in the development of welding technology.

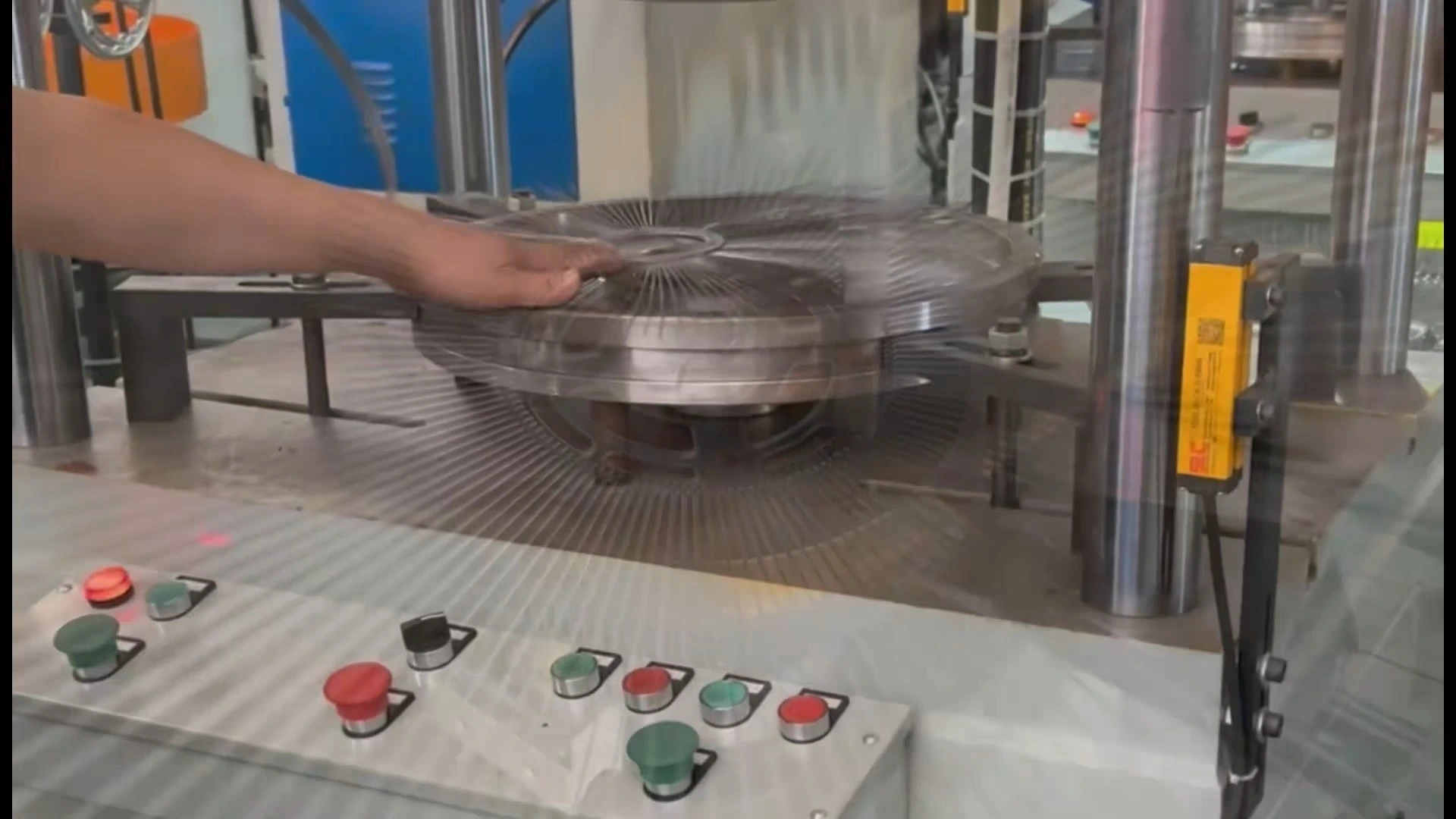

Four-Column Hydraulic Press for Fan Guard Mesh Cover Fabrication - Heavy Duty Oil Hydraulic Machine with Precision Forming

About This Product

Precision Forming & High-Efficiency Industrial Solution

Product Overview

Jinchun Four-Column Hydraulic Press is engineered for precision metal mesh forming, stretching, and stamping applications. Specifically designed for fan guard mesh covers, this hydraulic press delivers ±0.1mm forming accuracy and supports continuous production with a daily output of 1,500-2,000 units (based on 16"-24" mesh sizes), ensuring consistent product quality and operational efficiency.

Core Advantages

1. Dual Closed-Loop Hydraulic Control

• Integrated microcontroller unit (MCU) with 8 preset parameter modes for rapid switching between mesh sizes (e.g., 16" HVAC grilles vs. 24" automotive vents).

• Electro-hydraulic proportional valve system ensures stable pressure output (±2% fluctuation tolerance) even under voltage variations of ±15%.

2.High-Rigidity Frame Design

•Forged 45# steel frame with vibration-damped welding technology, providing 40% higher rigidity compared to conventional designs.

•Twin-column guide bushings (grade 45 steel, hardened to HRC58-62) minimize deflection during high-load operations.

3.Smart Safety System

•Infrared photoelectric safety fence with 0.5ms response time to prevent accidental operation.

•Dual-stage hydraulic overload protection (200T/300T pressure cutoff) to protect molds and components.

Technical Parameters

|

Voltage |

380V |

Type |

Four-column Three-beam Hydraulic Press |

|

Warranty Period |

1 year |

Weight (KG) |

2150 |

|

Place of Origin |

Guangdong, China |

Power |

7.5KW |

|

Current |

30-40A |

Platform square |

850*850mm |

|

Brand |

JCXLC |

Product Name |

25T Hydraulic Press Machine |

|

Power |

7.5KW |

Protection |

Infrared ray device |

|

Oil Pump |

PV2R1-28 |

Upper cylinder bore diameter |

140mm |

|

Upper cylinder pressing stroke |

350mm |

Lower ejector cylinder bore diameter |

80mm |

|

Certification |

CE |

Type |

Manual Bending Machine |

|

Suitable for |

Fan Guard/Bird Cage/Super Market Cart |

Transport Package |

Sea Worthy Wooden Package or PVC Film for FCL |

| Delivery Time | ||

|

Quantity (sets) |

1 - 1 |

> 1 |

|

Eastern Time in the US (days) |

15 |

To be determined |

| Customization | ||

|

Customized logo |

Minimum Order Quantity |

1 set |

|

Customized packaging |

Minimum Order Quantity |

1 set |

|

Graphic customization |

Minimum Order Quantity |

1 set |

Product Display

Product Information

|

Brand Name |

Jinchun / JCXLC |

|

Country of Origin |

Foshan, Guangdong, China |

|

Loading Port |

Foshan / Shenzhen / Guangzhou |

|

Payment Terms |

EXW / FOB / CIF |

product introduce

Faq