Fabricante líder de máquinas formadoras de alambre especializado en el desarrollo de tecnología de soldadura.

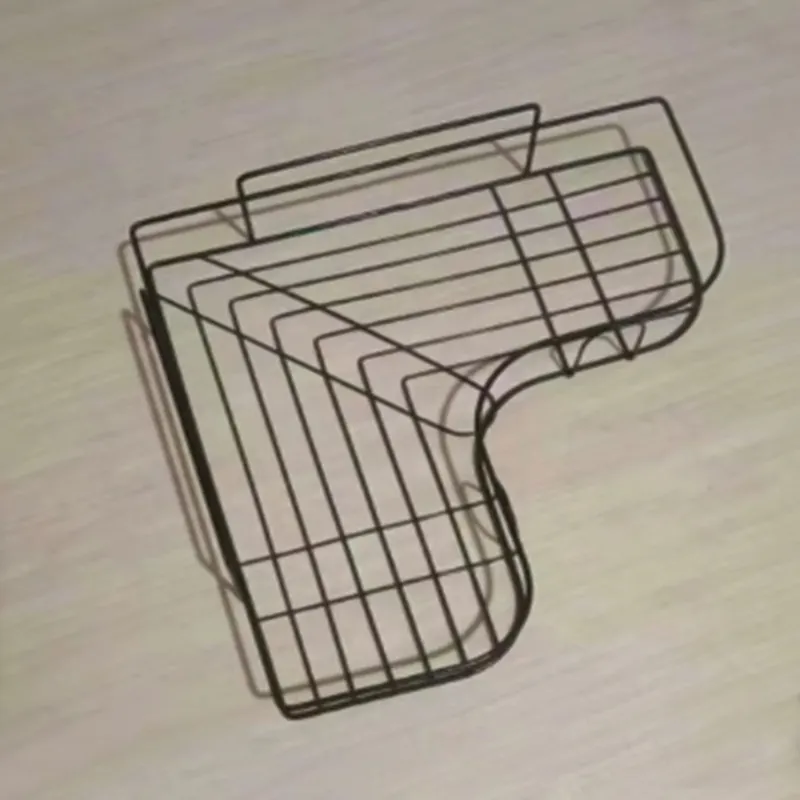

Máquina dobladora de alambre de XLC

Descripción general del producto

- La máquina dobladora de alambre de XLC está equipada con un dispositivo de corte hidráulico y un dispositivo de asiento deslizante móvil para una alta estabilidad.

- Es adecuado para procesar materiales de alambre de acero inoxidable como forja, tornos automáticos, barras, tornillos, husillos, acero, latón, hierro y otros metales.

- La apariencia del alambre se mantiene sin daños, lo que garantiza el atractivo estético.

- Cuenta con un sistema de control de ingeniería eléctrica según estándar CE para seguridad, baja tasa de fallas, buena funcionalidad y mayor productividad.

- La máquina tiene un bajo consumo y no desgasta los rodillos de la enderezadora.

Características del producto

- Los componentes principales incluyen PLC y motor.

- Los materiales procesables incluyen acero inoxidable.

- El peso es de 1000 KG

- Periodo de garantía de 1 año

- El nivel de automatización es completamente automático.

Valor del producto

- La máquina dobladora de alambre ofrece alta estabilidad, eficiencia y precisión en el doblado de materiales de alambre de acero inoxidable.

- Está equipado con tecnología avanzada y un sistema de control para mayor productividad y seguridad.

- La máquina está diseñada para mantener el atractivo estético de los cables sin dañarlos.

- Hay opciones de personalización disponibles para el logotipo, el embalaje y el diseño gráfico.

- El producto viene con garantía e inspección previa al envío para asegurar la calidad.

Ventajas del producto

- Multifuncional con la función adicional de soldadura.

- Funcionamiento totalmente automático para facilitar su uso.

- Adecuado para diversas aplicaciones de doblado de alambre.

- Construcción duradera y de alta calidad.

- Ventas rápidas y servicio posventa las 24 horas proporcionado por la fábrica.

Escenarios de aplicación

- La máquina dobladora de alambre es ideal para industrias y campos que requieren doblado de precisión de materiales de alambre de acero inoxidable.

- Se puede utilizar en procesos de fabricación como forja, tornos automáticos, barras, tornillos, husillos, entre otros.

- Adecuado para empresas que buscan mejorar la productividad, la eficiencia y la seguridad en las operaciones de doblado de alambre.

- Las opciones personalizables lo hacen versátil para diferentes aplicaciones y necesidades de marca.

- La máquina es adecuada tanto para escenarios de producción a pequeña como a gran escala.